Freetime Beer Co.

2019 - 2025

The second iteration of the brewery project I started with my good friend Rich (previously West by Three).

My responsibilities include:

Operational

Financials, Project Management, Marketing, Email Campaigns & Bartending Festivals

Design Services

Branding, Artwork, Website, Packaging, Merchandise, Equipment, Plant & Space

Tech Stack

Customized Shopify Site, Bespoke Production Tracking App (Zoho), Zoho CRM integration, Xero integration & Google Workspace admin

Unfortunately, we were forced to rename our trademarked brand after a tedious & costly legal saga in 2018.

Rich & I work full-time jobs, Freetime seemed like the perfect name for our side hustle.

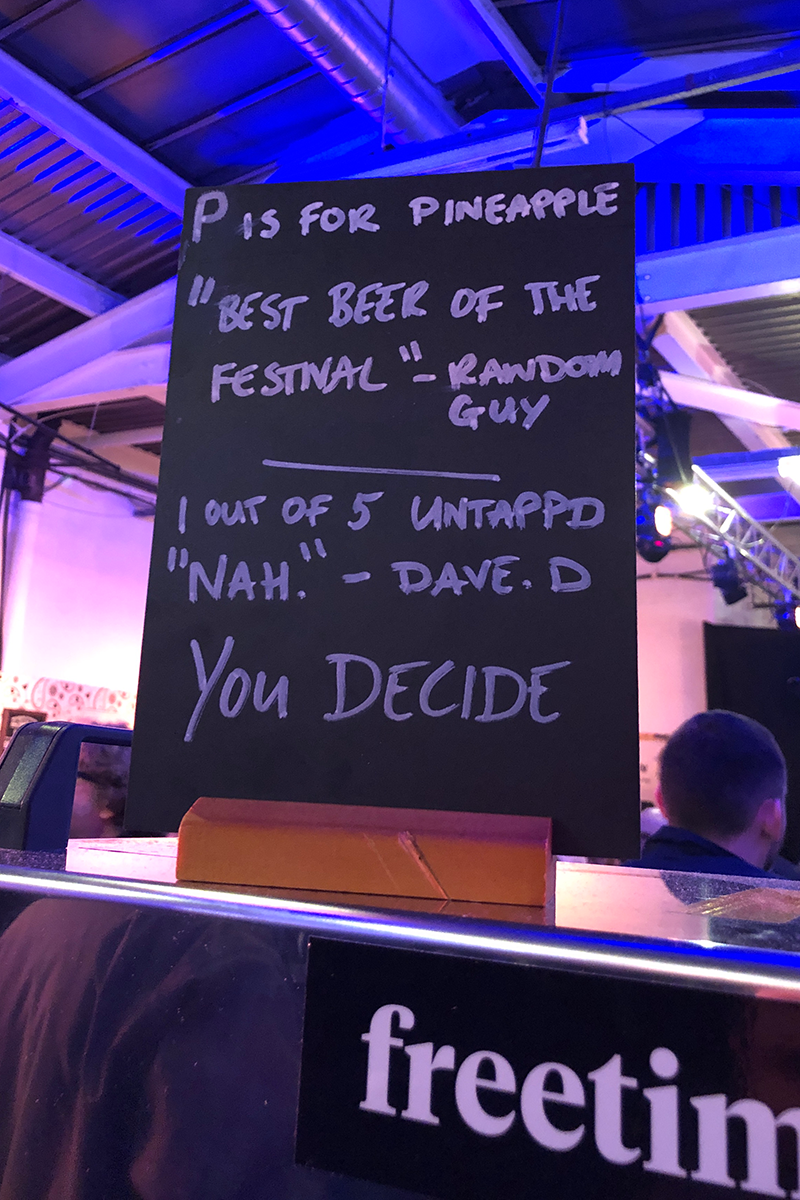

Freetime was born in February 2019, we poured the first beers under the new brand at the Craft Beer Rising festival in the Old Truman Brewery in East London.

I introduced the new branding with a merchandise pre-order marketing campaign before the festival.

The intention was to drum up support, engage our audience & cover the cost of the new gear.

Building on our success from 2018, we were oversubscribed.

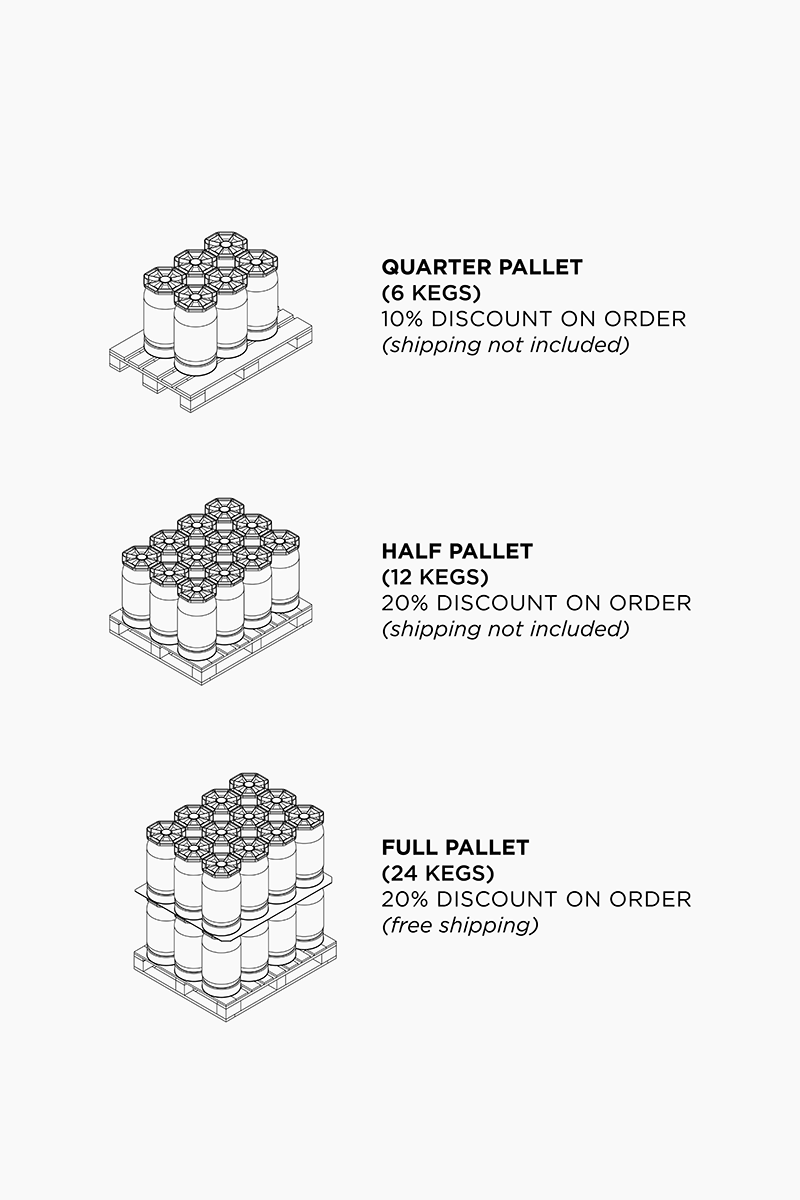

Due to demand we had stopped bottling & focused on shipping pallets of kegs.

We couldn't keep up with demand.

So we increased our production capacity & simplfied our eclectic line-up.

Our pale ale (Mating Surfaces) & Helles (Spezial) became our top sellers.

We invested in two new fermenters (FVs), allowing us to scale production of our two new core products.

Our lagers were popular.

We had identified a market for high quality canned craft lagers.

The next phase of our planned expansion in 2020 was to scale up our brew-house, purchase more FVs & a canning line.

Little did we know what was coming round the corner.

The covid-19 pandemic & the lock-down rules in the UK left our keg only model exposed, sales stopped overnight.

In October 2020 we dumped £40k of kegs that were past their sell date.

Hands down the most disappointing moment of my professional career.

It was hard for us to decide when/how to restart production.

One batch of beer did survive 2020.

At the end of 2019 we produced an Imperial Stout it spent lock-down in a bunch of Welsh Whisky barrels.

Our friends at BeerRiff, let us use their canning line to get it packaged & out for delivery for Christmas 2020.

Throughout 2021 & 2022 we produced collaborations with our friends BeerRiff.

Reducing the risk of being stuck with too much keg stock & their DTC sales channel to move the product through.

We started contract brewing, producing private label beers for venues in Wales.

This was a great way for us to use the brew-kit without holding inventory.

London based tech company Nothing approached us to brew them a rice lager for their Soho store launch party.

The first batch, beer (1) was a limited run & they printed each can with a handheld dot matrix printer.

It was a hit so we produced a full length run for them, beer (2) sold out in 3 days.

We continue to contract brew for select clients as we look for our dream retail & production venue.